2016 26.1 Selecting and Breeding Barley for Craft Malt and Organic Production in Western WA

Introduction

The key ingredients of craft beer are malted barley, hops, yeast and water. There are over 300 licensed breweries in Washington and every time someone sits down to enjoy a beer from one of these establishments they are relying on the production of barley. While there is a very good chance the hops have been sourced from Washington (Turner et al. 2011), until recently options for sourcing local and organic malt were very limited.

The malting and brewing industry is highly consolidated, with 10 companies controlling over 50% percent of the global malting market (Punda and Prikhodko 2009; Huvet 2014). In the United States most malting barley production occurs in North Dakota, Montana and Idaho, and breweries typically source malted barley from large North American and European malting companies. This is changing, however.

In the United States more than 30 craft malthouses have opened in the past 15 years aiming to meet demand for unique locally produced grains (Thomas 2013; Frank and Meltzer 2014; Stayton 2014; Rowe 2015). In Washington the establishment of craft maltsters, including Skagit Valley Malting, is creating opportunity for barley growers interested in marketing to local breweries and is creating opportunity for brewers and distillers interested in sourcing local grain.

Barley is grown on more than 6,000 acres in western Washington where it is commonly used as a rotation with high value vegetable crops (USDA NASS 2012). While organic barley is an important livestock feed, particularly for dairies, production of barley for malting gives growers another option to add value to local grain production. In order to produce beer from locally grown barley, the barley must be malted.

In the malting process grains are soaked, germinated, and dried. Key transformations that occur in the barley kernel during malting include degradation of structural components (such as beta-glucan), synthesis of starch degrading enzymes (primarily alpha and beta amylase) which convert starch to sugar during the mashing stage of brewing, and the release of amino acids which support yeast growth during fermentation (Briggs 1998). The drying or kilning stage of malting stabilizes the malted grain for storage and can be manipulated to alterflavor and color contributions.

Barley breeders have selected varieties to meet the needs of large malting and brewing companies including rapid germination and high levels of starch degrading enzymes necessary for adjunct brewing. Recently the growth of the craft brewing industry has led to increased demand for barley varieties with lower protein levels, and enzyme activity better suited to all malt brewing methods (Brewers Association 2014).

In western Washington the moderate temperatures and high levels of available moisture in the spring months are ideal for producing high yields of low protein barley. These growing conditions are also conducive to foliar diseases such as barley leaf rust (Puccinia hordei) and powdery mildew (Blumeria graminis). These diseases can reduce yield as well as the quality of barley. The fertile growing conditions and ample moisture common in western Washington can also contribute to lodging. Rain near harvest can cause preharvest sprouting which can negatively impact malting quality by reducing germination of the harvested grain.

Identifying malting barley varieties that can meet these challenges and grow well in organic conditions in western Washington is an important first step for expanding this potential market. As part of a larger study looking at the performance of malting barley at four locations in western Washington, malting barley varieties were grown in a certified organic field at WSU Mount Vernon (Brouwer 2015). In addition to variety trials, a breeding program was initiated in 2012 with the goal of selecting varieties with unique malting quality characteristics suited to organic production.

Methods

During the 2013 and 2014 seasons 12 barley varieties were grown in a randomized complete block design with three replicates. Entries included eight widely accepted malting varieties (Harrington, AC Metcalfe, CDC Copeland, CDC Meredith, Hockett, Newdale, Bentley and Full Pint), two locally adapted feed varieties (‘Baronesse’ and ‘Bob’), and two Washington State University (WSU) breeding lines (2004NZ151, subsequently released as ‘Richard,’ and 2004NZ170).

Plots were 12 ft x 4 ft and seed was planted in seven rows on six in centers at a rate of 120 lbs/acre using a modified Allis-Chalmers planting tractor. The field was fertilized with Proganic (8-2-4) at a rate of 70 lbs of N/acre prior to planting. Plots were harvested using a Winterstieger plot combine and grain was cleaned by wind machine prior to measuring yield and grain quality. During the growing season, severity of barley leaf rust and powdery mildew were rated as a percentage of leaf area. Agronomic traits including days to heading, plant height and percent lodging were also evaluated. Quality factors including grain protein, test weight, kernel plumpness (% >6/64 in), Falling number (seconds) and germination were measured after harvest. The falling number indirectly measures alpha amylase which is produced during germination; if a sample has a falling number below 220 seconds it is likely that preharvest sprouting has occurred (Tordenmalm et al. 2004; Schwarz et al. 2004).

Results and Discussion

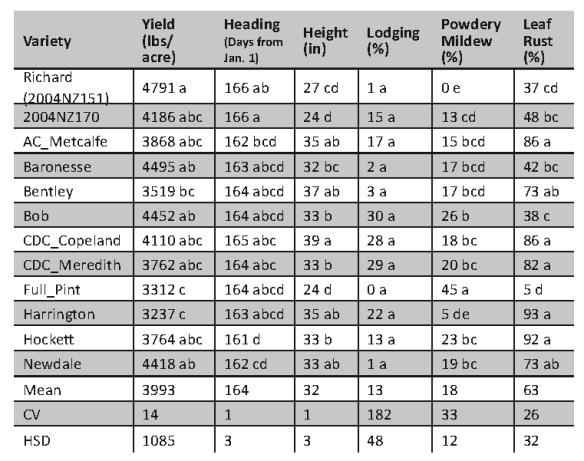

Significant differences between varieties were identified for key agronomic traits shown in Table 1. Over the two years of the study ‘Richard’ was the highest yielding variety with a mean yield of 4791 lbs per acre, which was significantly greater than ‘Bentley,’ ‘Full Pint,’ and ‘Harrington’. ‘Richard’ has been released by WSU based on its performance in western Washington and foundation seed will be available spring 2016. Plant height was significantly different between varieties, with the semi-dwarf varieties ‘Full Pint,’ ‘2004NZ170,’ and ‘Richard’ being the shortest. Semi-dwarf cultivars can be more resistant to lodging, however some organic growers prefer taller varieties to help shade out weeds. Lodging ranged from 0% for ‘Full Pint’ to 30% for ‘Bob,’ but differences were not significant, indicating the importance of local environmental conditions in causing lodging. Varieties with disease resistance are particularly important for organic growers who don’t have access to chemical fungicides. ‘Full Pint’ had significantly lower leaf rust severity than all other varieties except ‘Richard.’ ‘Richard’ had significantly lower powdery mildew severity than all other varieties except ‘Harrington.’

Table 1. Mean yield, days to heading, height, lodging, powdery mildew and leaf rust severity for barley varieties grown in organic trials in Mount Vernon, WA in 2012 and 2013. Groups with the same letter subscript are not significantly different based on Tukey’s pairwise comparison (p=0.05). Honest Significant Difference (HSD) indicates smallest significant difference between to means.

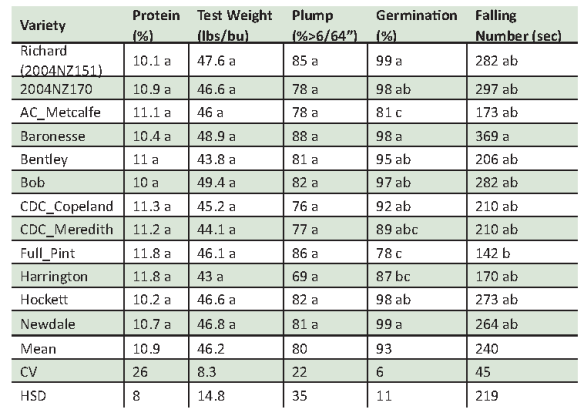

There were also significant differences between varieties for germination and falling number, though varieties evaluated were not significantly different for protein, test weight, or plump kernels as shown in Table 2. ‘Full Pint’ had the lowest percent germination (78%) which was significantly lower than ‘Newdale,’ ‘Richard,’ ‘Baronesse,’ ‘2004NZ170,’ ‘Bentley,’ ‘Bob,’ CDC ‘Copeland’ and ‘Hockett.’ ‘Full Pint’ also had the lowest falling number indicating that pre-harvest sprouting was responsible for reducing the germination of this variety. Susceptibility to pre-harvest sprouting has been found to be linked to high levels of starch degrading enzymes typical of standard malting varieties (Ullrich et al. 2009; Castro et al. 2010; Jin et al. 2011; Edney et al. 2013). Varieties that balance malting quality with resistance to pre-harvest sprouting will be particularly important for malting barley production in western Washington. Pilot malt testing of ‘Richard’ by Skagit Valley Malting has demonstrated that this variety has considerable potential for craft malt even though it was originally rejected by the industrial malting industry (Brouwer 2015).

Table 2. Mean protein, test weight, plump kernels, germination and falling number for barley varieties grown in organic trials in Mount Vernon, WA in 2012 and 2013. Groups with the same letter subscript are not significantly different based on Tukey’s pairwise comparison (p=0.05). Honest Significant Difference (HSD) indicates smallest significant difference between to means.

In parallel to these variety trials a breeding program was initiated in 2012 to select barley specifically for organic production in western Washington. A total of 56 successful crosses were made between 2012 and 2013 using North American and European feed and malting varieties as well as novel and/or disease resistant germplasm as parent lines. F2 seed was produced in the greenhouse and all subsequent selections were conducted in certified organic field trials at WSU Mount Vernon. Populations were evaluated for days to heading, resistance to leaf rust, stripe rust, and powdery mildew as well as lodging. In 2013 a total of 35 F2 populations were evaluated in the field and 16 populations were advanced, 50 heads were randomly collected from each bulk F2 population. In spring 2014, 768 F3 head-rows were planted and 40 selections were advanced to trials in 2015 . Of these F4 lines 19 were selected for continued evaluation based on general agronomic appearance, disease resistance and novel pedigree. This is an ongoing breeding program and feed back from brewers, maltsters, distillers and growers continues to guide the selection process.

Conclusion

Growers interested in producing organic malting barley should pay special attention to identifying varieties with excellent resistance to foliar pathogens, and yield potential under low input conditions. Important grain quality parameters include large kernel size, moderate to low protein content, and resistance to pre-harvest sprouting. Growers may also need to work directly with a maltster to confirm that they have the capacity and interest to malt novel, locally-adapted varieties. Place-based plant breeding that engages producers, processors and other end-users in the process of identifying priorities and making selections has the potential to play an important role in strengthening local agriculture (Brouwer et al. 2015). Through a combination of variety evaluation and breeding work options for organic barley growers interested in producing malting barley are becoming increasingly available.

Brook Brouwer completed his PhD research in Crop Science at WSU under the direction of Stephen Jones in August 2015 and is currently working as a research associate with the Organic Seed Alliance based in Port Townsend, WA. Stephen Jones is a Professor in the Department of Crop Science at Washington State University, and director of the Bread Lab.

Acknowledgements

The authors wish to acknowledge Steve Lyon for assistance in field trials and breeding work; Skagit Valley Malting for conducting a pilot malting trial of ‘Richard.’ Funding for this project was provided by the Port of Skagit and the Clif Bar Family Foundation Seed Matters Initiative.

Additional Resources

thebreadlab.wsu.edu/western-washington-variety-trials/

barleyworld.org/

www.craftmalting.com/

www.cmbtc.com/CMBTC_Site/Home.html

References

Brewers Association. 2014. Malting barley characteristics for craft brewers. Brewers Association. www.brewersassociation.org/best-practices/malt/malting-barley-characteristics/.

Briggs, D.E. 1998. Malts and malting. London; New York: Blackie Academic.

Brouwer, B. 2015. Plant Breeding for Regional Food Systems: Investigating Craft Malt, Disease Resistance and Production Potential of Barley and Dry Beans in Western Washington. Doctor of Philosophy, Pullman, WA: Washington State University.

Brouwer, B.O., K.M. Murphy, and S.S. Jones. 2015. Plant breeding for local food systems: A contextual review of end-use selection for small grains and dry beans in western Washington. Renewable Agriculture and Food Systems FirstView (June): 1–13. doi:10.1017/S1742170515000198.

Castro, A.J., A. Benitez, P.M. Hayes, L. Viega, and L. Wright. 2010. Coincident quantitative trait loci effects for dormancy, water sensitivity and malting quality traits in the BCD47 × Baronesse barley mapping population. Crop and Pasture Science 61 (9): 691–99. doi:10.1071/CP10085.

Edney, M.J., W.G. Legge, M.S. Izydorczyk, T. Demeke, and B.G. Rossnagel. 2013. Identification of barley breeding lines combining preharvest sprouting resistance with “Canadian-type” malting quality. Crop Science 53 (4): 1447–54. doi:10.2135/cropsci2012.11.0649.

Frank, S., and A. Meltzer. 2014. Craft Malting: Germination of a new industry. American Brewer.

Huvet, D. 2014. World largest commercial malting companies. First Key: Consultants to the Brewing and Malting Industries. firstkey.com/wp-content/uploads/World_Largest_Comm._Malting_Cies_-_FK_June-14.pdf.

Jin, X., S. Harasymow, Y. Bonnardeaux, A. Tarr, R. Appels, R. Lance, G. Zhang, and C. Li. 2011. QTLs for malting flavour component associated with pre-harvest sprouting susceptibility in barley (Hordeum vulgare L.). Journal of Cereal Science 53 (2): 149–53. doi:10.1016/j.jcs.2010.09.004.

Punda, I., and D. Prikhodko. 2009. Agribusiness handbook: Barley malt beer. Rome: FAO. www.fao.org/fileadmin/user_upload/tci/docs/AH3_BarleyMaltBeer.pdf.

Rowe, S. 2015. Local malting company creates flavors unique to Skagit County grain. Goskagit.com. www.goskagit.com/all_access/local-malting-company-creates-flavors-unique-to-skagit-county-grain/article_c7484aac-a28a-5120-b973-e5c16a110ae1.html.

Schwarz, P., C. Henson, R. Horsley, and H. McNamara. 2004. Preharvest sprouting in the 2002 Midwestern barley crop: Occurrence and assessment of methodology. Journal of American Society of Brewing Chemists 62 (4): 147–54.

Stayton, M. 2014. Malting business fires up new flavors. Skagit Valley Herald. www.goskagit.com/all_access/malting-business-fires-up-new-flavors/article_8de28612-1902-5f7d-a643-36bd1a1765db.html.

Thomas, D. 2013. Malting: the latest craft. Brewer & Distiller International.

Tordenmalm, S., M. Bason, S. Chan, A. Foster, P. Greer, D. Hatcher, H. He, M. Izydorczyk, D. Johnson, S. Kay, S. Kreisz, M.J. Maurice, H. McNamara, J. Sveinson, E. Svensson, J. Sortland, P. Whalen, and P. Schwarz. 2004. Sprout damage in barley. Journal of the ASBC 62 (1): 49–53. doi:10.1094/ASBCJ-62-0049.

Turner, S.F., C.A. Benedict, H. Darby, L.A. Hoagland, P. Simonson, J.R. Sirrine, and K.M. Murphy. 2011. Challenges and Opportunities for Organic Hop Production in the United States. Agronomy Journal 103 (6): 1645. doi:10.2134/agronj2011.0131.

Ullrich, S.E., H. Lee, J.A. Clancy, I.A. del Blanco, V.A. Jitkov, A. Kleinhofs, F. Han, D. Prada, I. Romagosa, and J.L. Molina-Cano. 2009. Genetic relationships between preharvest sprouting and dormancy in barley. Euphytica 168 (3): 331–45. doi:10.1007/s10681-009-9936-1.

USDA NASS. 2012. Quick Stats. United States Department of Agriculture/ National Agricultural Statistics Service. quickstats.nass.usda.gov/results/013F576F-36F2-3F75-AF8F-F08D6ED29E46.

Tags: Barley, barley leaf rust, low protein, malt production, Plant Breeding, powdery mildew, pre-harvest sprouting