2017 27.1 Mechanic Mike

This time of year I get a lot of questions about equipment maintenance. Though every piece of equipment deserves a good going over once a year, maintenance is an ongoing thing and shouldn’t be put off until winter. Here are a few tips to make periodic maintenance easier.

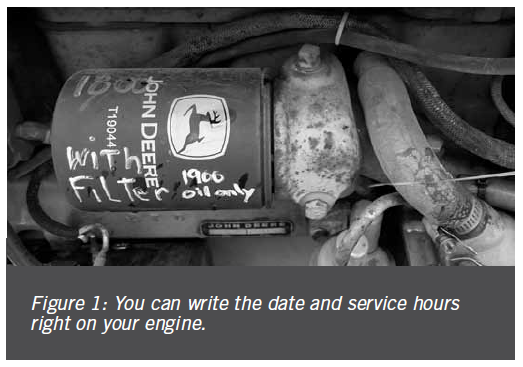

Most tractors require an oil change every 100 hours and a fresh filter every 200. Invest in a decent pan for capturing the used oil, and get some ‘used oil’ stickers on line from any industrial supply site. Most of the hassle of an oil change is in dealing with the used oil. If you buy oil in 5 gallon buckets and have a good drain pan with a spout, things get a lot more manageable. If you can easily pour the used oil into an empty oil bucket with a label and a tight fitting lid, you have secure and safe temporary storage. Use a paint marker to write the date and hours of the service on the new oil filter immediately after you install it (Figure 1). This is a great visual reminder of the maintenance needs of your equipment.

Your tractor’s steering and linkage require grease every ten hours, or so, of operation. Keep a grease gun at the location where you fuel your equipment. Conveniently, most tractors will also have about a ten hour capacity of fuel. If you have a grease gun handy and take the time to give everything a few shots every time you refuel, it will pay off in spades. Copy and laminate the lubrication diagram (available in the operator’s manual) and post it by the fuel. After a few rounds, greasing will become second nature.

Nothing is better for your equipment than observation. Check the oil every day before you operate equipment. Look under the equipment for drips and fluids. Take a look at all the soft rubber bits like hoses and belts and watch for wear, checking, cracks and rubbing. Check the battery. If there is excessive corrosion on the terminals, clean them. Check the wiring for loose connections and frayed wires. Checking equipment for loose nuts and play is critical in avoiding expensive repairs. In the case of tillers and mowers, grab a hold of stuff and jiggle it a little. Bearings wear out, but they do not typically fail catastrophically without warning. You will be able to feel slop in tiller shafts and wheel bearings if you put your shoulder to it.

And don’t forget about those field trucks and market vehicles. Put together a pre-trip inspection that includes checking all fluid levels, looking for leaks and checking the lights, defroster, horn, muffler, etc.

Consider spending some time this winter creating a few check lists and an inventory of fluids and filters to have on hand. Developing good habits and record keeping regarding periodic maintenance is critical. Consider using a white board with a grid created with permanent marker. Make four columns: list your equipment in a column on the left. In the next column, record the hours or mileage and the date of service. In the third column write the mileage/hours of the next scheduled service. The fourth column can be used for notes like big repairs or areas that need attention. Make it clearly visible and big enough to write on with erasable marker. And remember we are going for progress not perfection.

Will you grease your tractor at every fuel fill? Will you check the fluid levels of all your field and market trucks before operation? I’m guessing not. But nudging the needle in this direction is important, especially if your farm is growing. When you get to a point where you are no longer able to monitor every activity, this kind of recordkeeping and creating a culture where routine maintenance and observation are part of the daily operation will extend the life of your equipment, and help keep you and everyone around you safer and more comfortable.

Mike Peroni is here to answer all of your farm machinery and tool questions! A longtime Washington state farmer, he has learned a thing or two about repair and maintenance. He’s rooting for you to do repairs and machinery work yourself; however, he is not responsible for outcomes. Please take caution, be safe out there and do additional research as needed. Send your questions to